H36 China metal cnc combined lathe milling machine with live tool

Specification

|

Linear Guideway CNC Lathe Machine H360 |

|

|

max. swing over bed |

Φ360mm |

|

max. swing over slide |

Φ110mm |

|

Chuck/collet |

Pneumatic collet |

|

X axis max travel range |

600mm |

|

Z axis max travel range |

600mm |

|

Guide way |

High speed linear guide way |

|

Spindle speed |

2500 rpm |

|

Spindle nose |

A2-5 |

|

Spindle bore |

Φ48mm |

|

Bar through the spindle |

Φ38mm |

|

Fast feeding speed |

X:20 Z:20 m/min |

|

Main motor power |

3.7KW(servo) |

|

Tool size |

20*20 mm |

|

Tool quantity |

gang type tool holder |

|

X/Z min set unit |

0.001 mm |

|

X/Z positionaI accuracy |

0.01 mm |

|

X/Z Repositioning Accuracy |

0.005 mm |

|

Weight |

1.5 T |

|

Standard Configuration: |

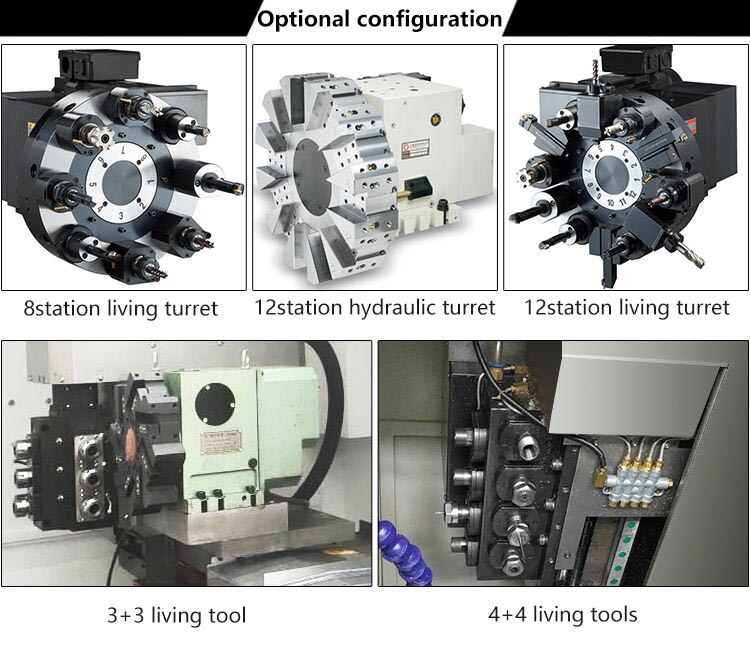

Optional Configuration |

|

GSK928 CNC Controller |

SIEMENS,FANUC,KND etc |

|

Taiwan HIWIN High speed Linear Guide way |

Living tool |

|

Auto lubrication system |

4 station tool holder |

|

Cooling System |

Speed Unit |

|

Lighting system |

|

|

Voltage:380v 3 phase (if your local have special request pls let us know) |

|

Features

1. Integral bed: The integral bed adopts integral structural castings, which have been treated with aging to provide strong rigidity and good stability.

2. Longitudinal feeding mechanism: The longitudinal feeding mechanism is installed under the bed head box and adopts a direct connection form. Through the nut seat fixed on the slide plate, the slide plate can realize longitudinal movement. The pre-tightening of the screw rod is achieved by tightening the nut to improve the tension and compression rigidity of the screw rod. The ball screw rod and the nut adopt a zero clearance fit.

3. Horizontal feed mechanism: The horizontal feed mechanism also adopts a direct connection form, and the worktable is driven by the nut seat to realize lateral movement. The horizontal feeding mechanism adopts the nut adjustment block fixed on the worktable for adjustment, which is convenient and reliable to adjust, and greatly improves the efficiency of the adjustment of the horizontal feeding mechanism.

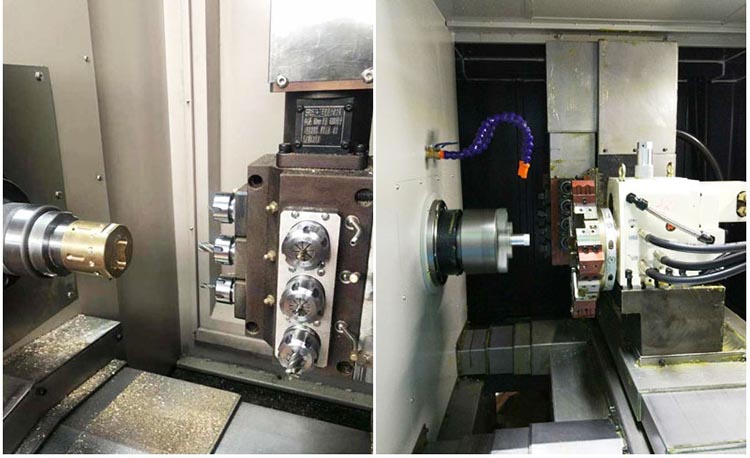

4. Both axes adopt linear rolling guides, drive without gaps, with good rigidity and high precision; there are multiple sets of fixed tool holders arranged on the long horizontal sliding plate, which can realize multi-process one-time processing with high precision.

The main shaft is driven by an AC servo motor, which can realize stepless speed change and constant linear speed cutting and high-speed cutting; the clamping device can also be installed with sleeve chucks, pneumatic power chucks, hydraulic chucks, etc. according to user requirements. The work piece is convenient and the work is reliable.

Packaging

Suitable for export seaborne packaging to ensure that the goods are packaged sturdy, safe and moisture-proof.

1. Non-fumigation packaging, we use seaworthy plywood. Packed in wooden cases without fumigation of plywood for export.

2. Steel base plate, it is stronger 3-5 times than normal plywood base plate.

3. Water-proof and damp proof, water resistant film wraped all the machine.

4. Fully sheathed case,prevention of collision and keep the goods intact.