C6136 /C6236 small horizontal metal manual lathe machine

Specification

|

Model |

C6 1/2 36C |

||

|

Processing capacity |

Max swing diameter over bed |

360 |

|

|

Max.swing over cross slide |

190 |

||

|

Maximum turning diameter at the saddle Maximum turning diameter at the saddle

|

520 |

||

|

Center distance |

750, 1000, 1500 |

||

|

Width of bed |

360mm |

||

|

Spindle |

Spindle bore |

Φ52/80mm |

|

|

Spindle nose |

C6 |

||

|

Spindle taper |

MT6 |

||

|

Spindle speeds range(Steps) |

40-1400 (9steps) |

||

|

Feed |

Metric threads(Number ) |

0.25-14mm (19kinds) |

|

|

Inch threads(Number ) |

2-40/inch |

||

|

Modular threads(Number ) |

0.25-3.5mπ (11kinds) |

||

|

Carriage |

Cross slide stroke

Cross slide stroke

|

180mm |

|

|

Tool rest stroke Small tool rest stroke

Small tool rest stroke

Small tool rest stroke

Small tool rest stroke

Small tool rest stroke

Small tool rest stroke

Small tool rest stroke

|

95mm |

||

|

section dimension

|

20 x 20mm² |

||

|

Tailstock |

Taper of tailstock sleeve |

MT4 |

|

|

Diameter of tailstock sleeve |

65mm |

||

|

Stroke of tailstock sleeve |

140mm |

||

|

Main motor |

4kw |

||

|

Package size: (L x W x H) |

|

||

|

Center distance 750mm |

2220 x 1150 x 1590mm |

||

|

1000mm |

2470 x 1150 x 1590mm |

||

|

1500mm |

2970 x 1150 x 1590mm |

||

|

Weight: NW/GW(KG) |

|

||

|

Center distance 750mm |

1350 |

2000 |

|

|

1000mm |

1450 |

2100 |

|

|

1500mm |

1600 |

2250 |

|

Main features of the product

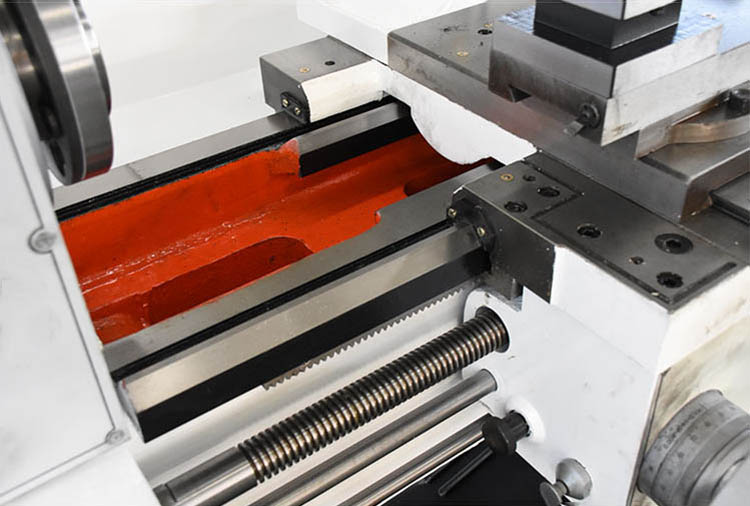

1. The bed and its legs are made of high-strength cast iron to ensure better accuracy, while reducing vibration and ensuring the stability of the machine tool for long-term use: the bed guide rails are precision ground after ultrasonic quenching to maintain the strength , Durable and wear-resistant, to ensure a longer service life of the machine tool, and also reduce the maintenance of the machine tool.

2. The headstock is processed by precision equipment to ensure the core parts of the machine tool are slightly required. At the same time, the bearings in the box are purchased from national brands. The spindle and gears are subjected to special methods such as high-frequency quenching and precision grinding to reduce the noise of the machine. Makes the overall performance of the machine a greater improvement. The joint surfaces between the headstock of the machine tool and the tailstock support plate of the machine tool are manually scraped and ground by the personnel. The whole machine has undergone strict testing to effectively ensure the accuracy and stability of the machine tool.

3. The unique speed change mechanism of the knife box can accurately transmit the speed change of the headstock part to the lead screw. The selection of metric and inch threads on the panel, the reference table of technical parameters, and various humanized designs ensure that operators can work quickly, safely and quickly.

4. Slide box, scientific analysis and calculation, reasonable gear transmission coordination. The rotation of the lead screw is accurately transmitted to the saddle horizontal and vertical feeds to ensure the realization of the machine tool size processing function.

5. The tailstock is processed from rough and fine turning, quenching, rough and fine grinding, and the whole machine is assembled with the headstock spindle for center contour correction to ensure the accuracy of the processed parts.

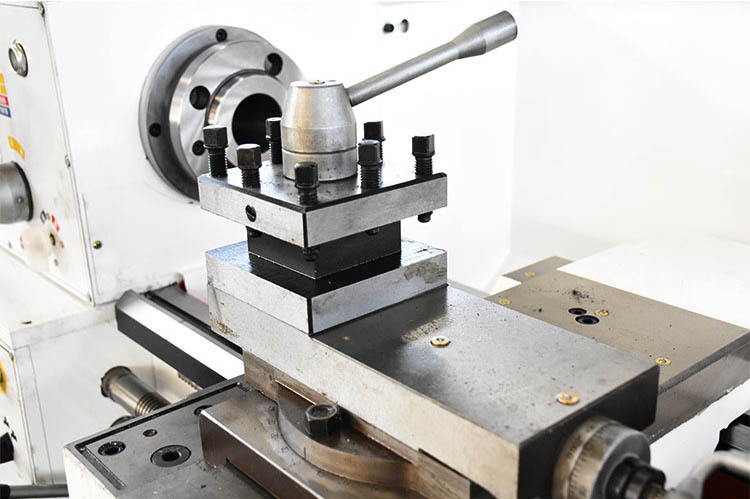

6. The design of the tool holder is exquisite, the tool clamping is convenient, and the four-station high-strength tool holder is adopted.

7. This machine adopts independent installation of water pump technology to ensure cooling and temperature reduction during the processing process to improve the accuracy of parts.

Conditions of machine use

1. Environmental requirements for the location of the machine tool: The location of the machine tool should be far away from the source of vibration, direct sunlight and thermal radiation, and moisture and airflow should be avoided. If there is a vibration source near the machine tool, an anti-vibration trench should be set around the machine tool. Otherwise, it will directly affect the machining accuracy and stability of the machine tool, and cause poor contact of electronic components, failures, and affect the reliability of the machine tool.

To

2. Power requirements: Generally, lathes are installed in the machining workshop, which not only has large environmental temperature changes and poor use conditions, but also has a lot of electromechanical equipment, which causes large fluctuations in the power grid. Therefore, the location where the ordinary lathe is installed requires strict control of the power supply voltage. The power supply voltage fluctuation must be within the allowable range and remain relatively stable. Otherwise it will affect the normal operation of the CNC system.

3. Temperature conditions: The ambient temperature of the general bed is less than 30 degrees Celsius, and the relative temperature is less than 80%. Generally speaking, an exhaust fan or air cooler is arranged inside the numerical control electric control box to keep the electronic components, especially the central processing unit's working temperature constant or the temperature difference changes very small. Excessive temperature and humidity will reduce the life of control system components and cause more failures. The increase in temperature and humidity and the increase in dust will cause adhesion on the integrated circuit board and cause short circuits.

4. Use the machine tool as specified in the manual: When using the machine tool, the user is not allowed to change the parameters set by the manufacturer in the control system at will. The setting of these parameters is directly related to the dynamic characteristics of each part of the machine tool. Only the value of the gap compensation parameter can be adjusted according to the actual situation. The user cannot replace the machine tool accessories at will, such as using a hydraulic chuck that exceeds the specification. When setting up accessories, the manufacturer fully considers the matching of various link parameters. Blind replacement causes mismatch of various link parameters, and even causes unexpected accidents. The pressure of the hydraulic chuck, hydraulic tool rest, hydraulic tailstock, and hydraulic cylinder should be within the allowable stress range, and any increase is not allowed.