vmc1060 factory metal 3 axis vertical cnc milling machine center

Advantage

1. Optional CNC turntable can form four-axis and five-axis coordinate linkage processing.

2. Optional automatic chip removal device, with the bed structure to ensure the internal cleanliness; optional spindle oil cooling, etc.

3. The casting undergoes two aging treatments to eliminate residual stress in the material.

4. X, Y, Z-direction guides can choose Taiwan's heavy-duty linear ball guides, which have the characteristics of fast speed, high rigidity, and so on.

Specification

| Item | VMC1060 | ||||

| Size of worktable(length×width)mm | 1300×600 | ||||

| T slot (mm) | 5-18×100 | ||||

| Max loading weight on worktable(KG) | 650 | ||||

| X-Axis travel(mm) | 1000 | ||||

| Y-Axis travel(mm) | 600 | ||||

| Z-Axis travel(mm) | 600 | ||||

| Distance between spindle nose and table(mm) | 100-700 | ||||

| Distance between spindle center and column(mm) | 667 | ||||

| Spindle taper | BT40/50 | ||||

| Max. spindle speed( rpm) | 8000/10000/12000 | ||||

| Spindle motor power(Kw) | 11/15 | ||||

| Rapid feeding speed: X,Y,Z axis (m/min) | 16/16/16 (24/24//24 liner guidway) | ||||

| Fast cutting speed (m /min) | 10 | ||||

| Positional accuracy (mm) | ±0.005 | ||||

| Repeat positional accuracy (mm) | ±0.003 | ||||

| Auto Tool changer type | 16 tools head type tool changer(optional 24 arm type auto tool changer) | ||||

| Max. tool length (mm) | 300 | ||||

| Max. Tool diameter | Φ80(adjacent tool)/φ150(not adjacent tool) | ||||

| Max.tool weight(KG) | 8 | ||||

| Tool changing time(tool-to-tool)sec | 7 | ||||

| Air pressure(Mpa) | 0.6 | ||||

| Machine weight(KG) | 7500 | ||||

| Overall sizse(mm) | 3340*2800*2700 | ||||

Why choose us

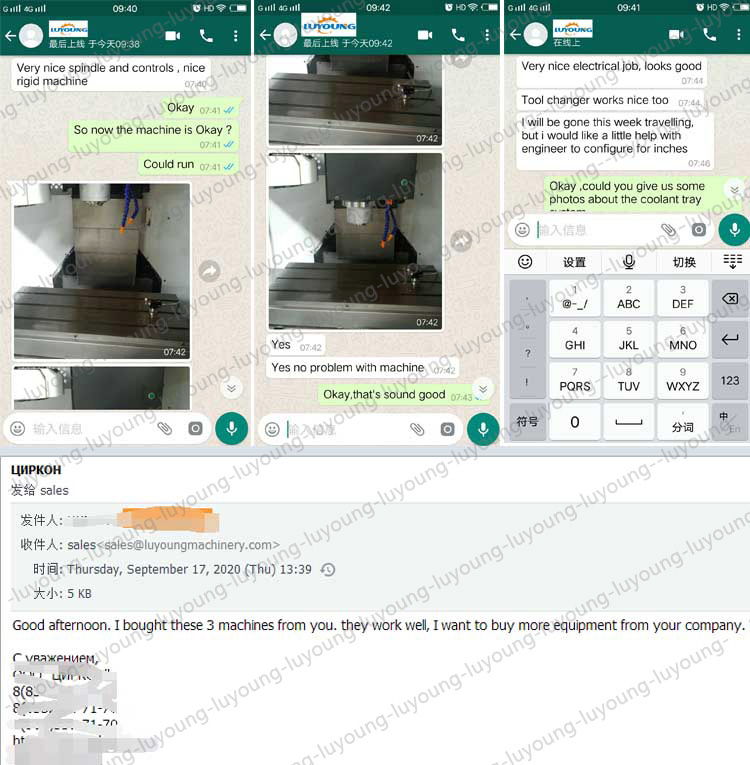

We receive a lot of good feedback from customers,for example:

Very Nice spindle and controls, nice rigid machine. Very nice electrical job,looks good.

Tool changer works nice too.

I bought 3 machines from you. They work well, I want to buy more equipment from your company.

Machine testing

1. The detection of linear motion positioning accuracy should be carried out under no-load conditions, and laser measurement shall prevail.

2. Repetitive positioning accuracy detection of linear motion, the instrument used for detection is the same as that used to detect positioning accuracy.

3. Detection of the return accuracy of the origin of linear motion.

4. Reverse error detection of linear motion is measured multiple times (generally 7 times) at three positions near the midpoint and both ends of the stroke, and the average value of each position is calculated, and the maximum value of the average value obtained is the inverse Error value.