AWR25 diamond cutting cnc lathe for alloy wheel repair and rim refurb

Specification of alloy wheel repair machine

|

Alloy wheel repair machine |

AWR22 |

AWR25 |

AWR28 |

AWR32 |

|

|

CNC controller |

Touch Screen Operation 17" LCD Display |

||||

|

Max. swig over bed Dia. |

610 |

Φ635 |

Φ770 (30’) |

Φ880(34’) |

|

|

Max. Load alloy wheel Size |

22inches |

22 inches |

28 inches |

32 inches |

|

|

Adjustable stroke of carrier in X direction |

100mm |

100mm |

100mm |

100mm |

|

|

Cross slide travel (mm) |

300 |

320 |

390 |

450 |

|

|

Width of the rail (mm) |

260 |

300 |

330 |

400 |

|

|

Length of the rail (mm) |

500 |

700 |

750 |

750 |

|

|

Clamping type |

10' chuck /self-centering |

12' chuck/self-centering wheel clamping |

16' chuck/self-centering wheel clamping |

||

|

Probe type |

Probe or laser |

||||

|

Range of spindle speed (RPM) |

50~2500 |

50~2500 |

50~2000 |

50~1800 |

|

|

Spindle speed control |

Automatic |

Automatic |

Automatic |

Automatic |

|

|

Spindle bore (mm) |

Φ60 |

Φ60 |

Φ82 |

Φ82 |

|

|

Max. size of tool post |

25×25mm |

25×25mm |

25×25mm |

25×25mm |

|

|

Stations of tool carrier |

4 position |

4 position |

4 position |

4 position |

|

|

Min. setting unit of motor |

(Z) long 0.001mm |

||||

|

(X) cross 0.001mm |

|||||

|

Moving speed of post |

(Z) long 8m/min |

||||

|

(X) cross 6m/min |

|||||

|

Motor power |

4KW |

4kw |

5.5KW |

7.5KW |

|

|

Surface roughness |

Ra 0.8-1.6 |

||||

|

Machine size |

(L×W×H) (mm³) |

1900*1400*1750 |

2100*1500*1750 |

1990 ×1600×1860 |

2470×1660×2080 |

|

Package size(mm) |

2000*1400*1750 |

2200*1500*1950 |

2150×1750×2100 |

2620×1810×2300 |

|

|

Net weight |

1300kg |

1700kg |

2000kg |

2500kg |

|

Features

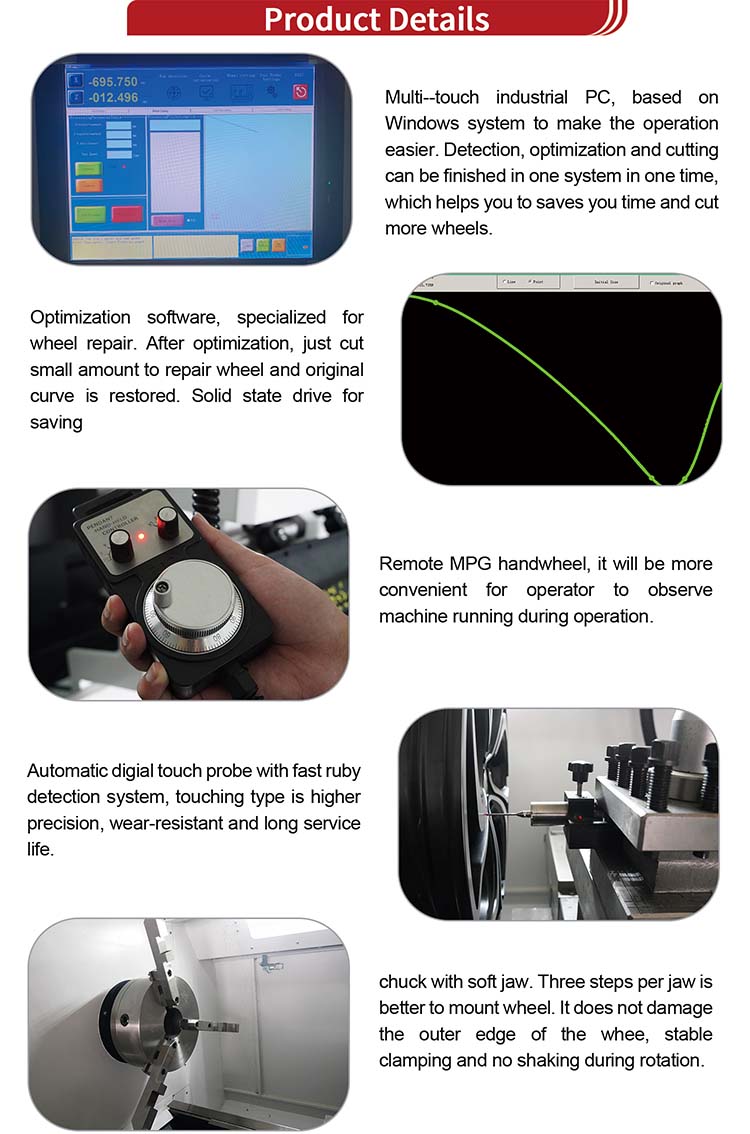

1. Muli--touch industrialPC,based onWindows system to make the operation easier. Detection, optimization and cutting can be finished in one system in one time,which helps you to saves you time and cut more wheels.

2. Optimization software, specialized for wheel repair. After optimization, just cut small amount to repair wheel and original curve is restored. Solid state drive for saving.

3. Remote MPG handwheel, it will be more convenient for operator to observe machine running during operation.

4. Automatic digial touch probe with fast ruby detection system, touching type is higher precision, wear-resistant and long service life.

5. chuck with soft jaw. Three steps per jaw is better to mount wheel. It does not damage the outer edge of the whee,stable clamping and no shaking during rotation.

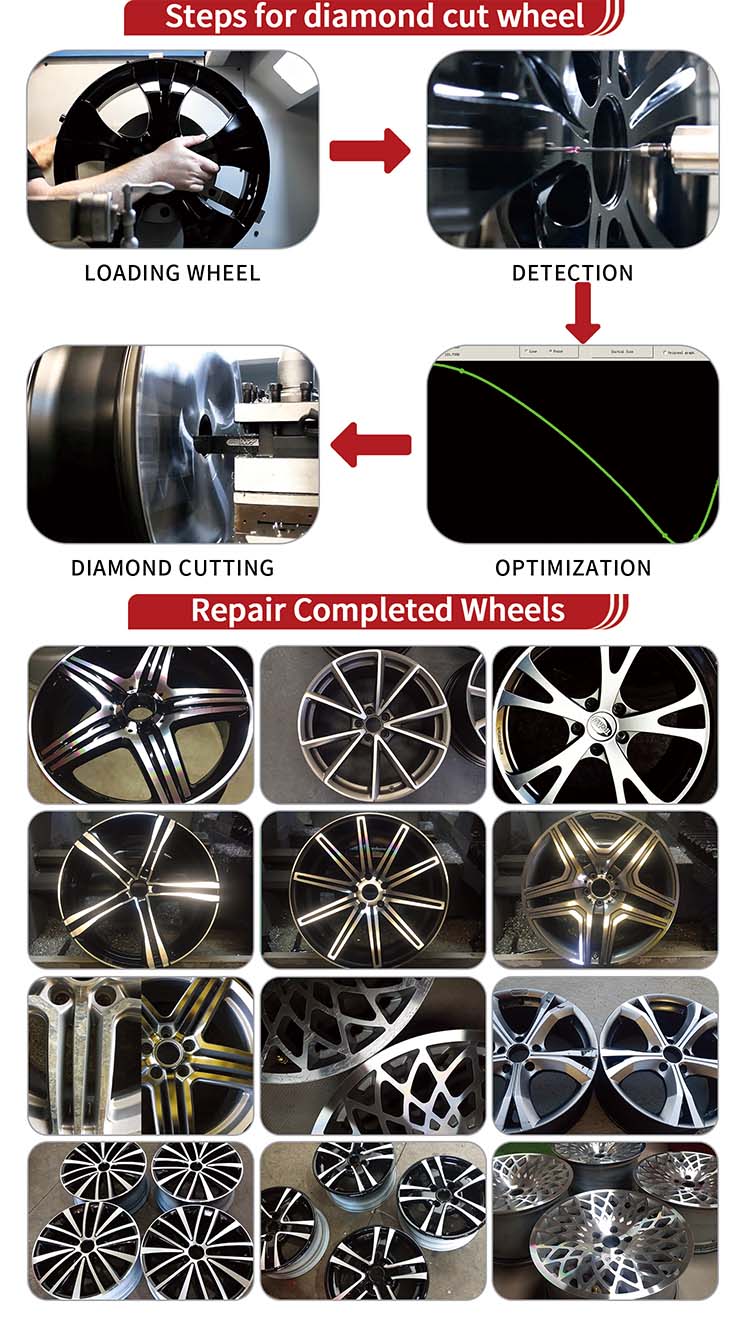

Steps for diamond cut wheel

1. Loading wheel: Put the wheel hub to be repaired in the correct position.

2. Detection, infrared probe detects the surface of the hub.

3. Optimization, a dedicated operating system analyzes and integrates data.

4. Diamond cutting, start turnin processing.