Awr22 diamond cutting alloy wheel rim repair machine

Our company has developed newest PC controller to repair damaged wheel face. The machine use 17'' touch industrial PC, so the machine get rid of complicated operation and many useless CNC controller button. And all steps will finished on PC.

Specification of alloy wheel repair machine

|

Alloy wheel repair machine |

AWR22 |

AWR25 |

AWR28 |

AWR32 |

|

|

CNC controller |

Touch Screen Operation 17" LCD Display |

||||

|

Max. swig over bed Dia. |

610 |

Φ635 |

Φ770 (30’) |

Φ880(34’) |

|

|

Max. Load alloy wheel Size |

22inches |

22 inches |

28 inches |

32 inches |

|

|

Adjustable stroke of carrier in X direction |

100mm |

100mm |

100mm |

100mm |

|

|

Cross slide travel (mm) |

300 |

320 |

390 |

450 |

|

|

Width of the rail (mm) |

260 |

300 |

330 |

400 |

|

|

Length of the rail (mm) |

500 |

700 |

750 |

750 |

|

|

Clamping type |

10' chuck /self-centering |

12' chuck/self-centering wheel clamping |

16' chuck/self-centering wheel clamping |

||

|

Probe type |

Probe or laser |

||||

|

Range of spindle speed (RPM) |

50~2500 |

50~2500 |

50~2000 |

50~1800 |

|

|

Spindle speed control |

Automatic |

Automatic |

Automatic |

Automatic |

|

|

Spindle bore (mm) |

Φ60 |

Φ60 |

Φ82 |

Φ82 |

|

|

Max. size of tool post |

25×25mm |

25×25mm |

25×25mm |

25×25mm |

|

|

Stations of tool carrier |

4 position |

4 position |

4 position |

4 position |

|

|

Min. setting unit of motor |

(Z) long 0.001mm |

||||

|

(X) cross 0.001mm |

|||||

|

Moving speed of post |

(Z) long 8m/min |

||||

|

(X) cross 6m/min |

|||||

|

Motor power |

4KW |

4kw |

5.5KW |

7.5KW |

|

|

Surface roughness |

Ra 0.8-1.6 |

||||

|

Machine size |

(L×W×H) (mm³) |

1900*1400*1750 |

2100*1500*1750 |

1990 ×1600×1860 |

2470×1660×2080 |

|

Package size(mm) |

2000*1400*1750 |

2200*1500*1950 |

2150×1750×2100 |

2620×1810×2300 |

|

|

Net weight |

1300kg |

1700kg |

2000kg |

2500kg |

|

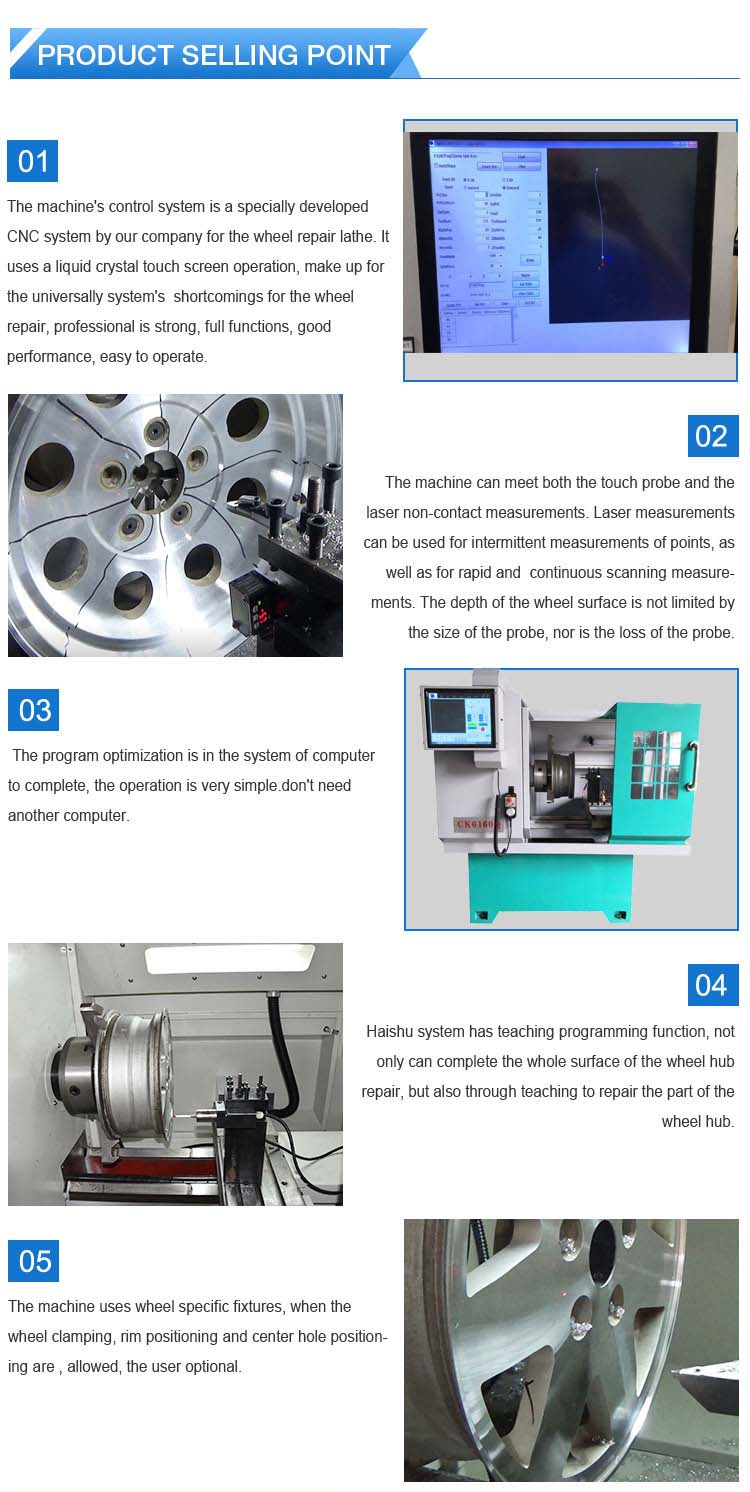

Advantage

1. The wheel lathe has the advantages of simple structure, low cost and high performance price ratio.

2. The machine tool can be selected by laser scanning or probe click measurement.

3. Wheel data is automatically stored, machining program is arbitrarily called out.

4. Software independent development, program automatically optimize

5. Wheel processing is automatic precise and fast

6. The machine tool is operated by touch screen, and the system interface supports many languages.

7. X / Z axis measurement, wheel surface and circumferential machining.

8. The wheel machine is equipped with an automatic lubrication system.

9. The lathe with diamond tool turning, make wheel surface more smooth.

10. The wheel repair lathe has the teaching function of the computer.

11. The machine can be customized according to customer requirements

Operational requirements

1. When two people are working, the operator behind the equipment must not face the exit of the wire drawing machine, so as to prevent the workpiece from flying out and hurting people.

2. It is strictly forbidden to adjust the wire drawing depth of the wheel hub under normal operating conditions, so as to avoid equipment and personal accidents caused by the loss of control of the turning tool.

3. Install the hub correctly. Carefully check whether the upper and lower bearing seats and the lifting screw are well lubricated, and make sure that there is no one on the front of the discharge before starting the machine.

4. The depth adjustment of the drawing machine should be moderate. Under normal circumstances, the drawing depth indication should be between 0.2-0.05, and it is strictly forbidden to exceed 0.3MM to avoid equipment or personal accidents.

5. It is strictly forbidden to put the work piece directly on the fixture, and it is strictly forbidden to put the work piece and draw the wire without closing the working door and without the blocking strip, so as to avoid the work piece flying out and hurting people.

6. After the hub wire drawing machine is started, immediately check whether the hub swing is within the required range and whether there are other abnormal phenomena, otherwise, it should be adjusted or shut down immediately.

Repair completed wheels showing