Best quality China Tck46A Lathes CNC Lathe Turning Machine Price

“Sincerity, Innovation, Rigorousness, and Efficiency” would be the persistent conception of our corporation to the long-term to establish collectively with customers for mutual reciprocity and mutual benefit for Best quality China Tck46A Lathes CNC Lathe Turning Machine Price, At our firm with quality first as our motto, we manufacture products that are entirely made in Japan, from materials procurement to processing. This enables them to be used with confident peace of mind.

“Sincerity, Innovation, Rigorousness, and Efficiency” would be the persistent conception of our corporation to the long-term to establish collectively with customers for mutual reciprocity and mutual benefit for China Lathe CNC, Lathe Machine Tools, Only for accomplishing the good-quality product to meet customer’s demand, all of our goods have been strictly inspected before shipment. We always think about the question on the side of the customers, because you win, we win!

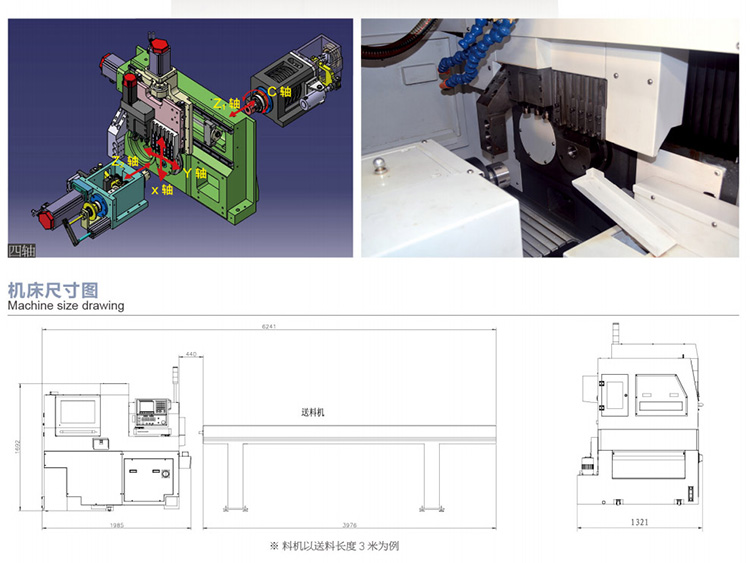

Feature of AK164

1. High-speed, high-precision, and high-efficiency: The tool layout is optimal, and the control system adopts high-speed calculation processing to minimize the tool change time, obtain the best positioning, and minimize the auxiliary time.

2. High stability: The guide rail and span structure are widened, and the brake locking device after the main/secondary axis indexing improves the stability when the workpiece is processed.

3. High configuration: The multi-axis tool configuration is rich, and the power tool is standard, which greatly expands the processing range and satisfies the complex processing of complex parts.

4. High rigidity: the wall thickness of the bed casting, the wide span of the guide rail, the rigidity and expansibility of the machine tool. Heavy cutting is superior to other machine tools and has obvious advantages in processing steel, alloy steel, stainless steel, etc.

Specification

|

Describe |

Unit |

AK164 |

|||

|

Mechanic |

Controller system |

|

Fanuc 0i |

Syntec |

|

|

Max maching diameter |

mm |

¢16 |

|||

|

Stroke |

mm |

150 |

|||

|

Main Spindle /Sub spindle RPM |

rpm |

10000/8000 |

6000/6000 |

||

|

Rapid traverse speed |

m/min |

24 |

|||

|

Tools |

O.D Tools |

ea |

6×[□12×12] |

||

|

Front Work Tools |

ea |

3×[Ø25-ER16] |

|||

|

Cross Driven Tools |

ea |

3[ER16] |

|||

|

Back end tools(fixed) |

ea |

/ |

/ |

||

|

Motors |

Spindle motor |

kw |

3.7/5.5 |

3.7 |

|

|

Sub Spindle motor |

kw |

0.55/1.1 |

0.4 |

||

|

Driven |

kw |

0.75 |

|||

|

Cross |

kw |

0.5 |

|||

|

Coolant motor |

kw |

0.25 |

|||

|

Others |

Coolant tank capacity |

L |

180 |

||

|

Lubrication tank capacity |

L |

1.8 |

|||

|

Height from floor tospindle center |

mm |

1050 |

|||

|

Dimension |

(L) |

mm |

1985 |

||

|

(W) |

mm |

1321 |

|||

|

(H) |

mm |

1692 |

|||

|

Weight |

kg |

3000 |

|||

|

NC Control |

Controllable Axes |

5axis/4axis |

|||

|

LCD |

LCD 8.4″ |

||||

|

System standard parameters |

Standard |

||||

|

Rigid tapping |

Standard |

||||

|

Hand wheel |

Standard |

||||

|

Synchronous/hybrid control |

Standard |

||||

|

Helical interpolation |

Standard |

||||

Application of AK164 swiss type cnc lathe machine

It is suitable for industries such as automobiles, electronics, communications, IT, medical, military, aviation, hardware, machinery and hydraulic accessories. It is characterized by the ability to produce large quantities, high precision, and complex small and medium-sized parts.

Technical advantages

1) The trend of adopting high-speed built-in electric spindle is becoming more and more obvious, and the maximum speed of the spindle has reached 12500rpm/min.

2) The speed/position loop feedback adopts new components such as built-in high-resolution grating or magnetic, which has higher control accuracy of rotation and feedback.

3) The opposing dual-spindle cloth structure can complete full-sequence machining in one clamping, reducing the efficiency and machining accuracy problems caused by the secondary clamping of the workpiece, and improving the processing efficiency.

4) Multi-axis multi-tool control and multi-axis linkage technology improve the ability of machine tools to process complex parts and the efficiency of processing. The number of control axes of the machine tool is seven, and the number of non-powered tools and powered tools is more than 20.

5) Abundant automatic configuration to achieve the goal of one-man multi-machine operation and management, in addition to traditional bar conveyors, chip conveyors, etc., such as workpiece long/short workpiece receiver, automatic tool setting instrument, workpiece intelligent identification, workpiece Automatic pop-up detection, tool breakage detection, etc. have been successfully implemented in products to improve the level of automation and monitoring of machine tools.

Quality Inspection

The company formulates and implements strict internal control standards for quality management to achieve strict monitoring of the entire machine tool design and manufacturing process.

45 inspection and testing items, 632 quality control points, 48 hours to adjust the full stroke load processing test, using three coordinates.

Measuring instrument, British ERNISHAW laser F interferometer, Japanese SIGMA dynamic balance instrument and other top precision testing equipment in the world, guarantee.

Accurate control of all details of the machine tool.

“Sincerity, Innovation, Rigorousness, and Efficiency” would be the persistent conception of our corporation to the long-term to establish collectively with customers for mutual reciprocity and mutual benefit for Best quality China Tck46A Lathes CNC Lathe Turning Machine Price, At our firm with quality first as our motto, we manufacture products that are entirely made in Japan, from materials procurement to processing. This enables them to be used with confident peace of mind.

Best quality China Lathe CNC, Lathe Machine Tools, Only for accomplishing the good-quality product to meet customer’s demand, all of our goods have been strictly inspected before shipment. We always think about the question on the side of the customers, because you win, we win!