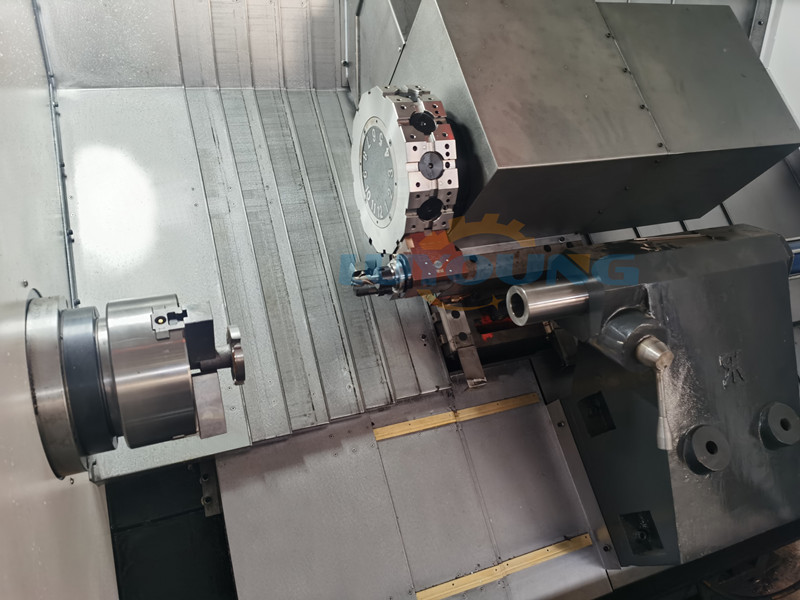

1. Good stability and large parts that need to be processed are generally inclined bed or flat bed inclined guide machine tools, because the corresponding parts of medium and large machine tools are also large, especially the turret part. The use of inclined guide rails is mainly to overcome gravity better. The stability of the machine tool can improve the accuracy of the machine tool, and it can reflect the superiority of the inclined machine tool in some harsh environments.

2. Improve space utilization. Inclined machine tools can effectively use space and greatly reduce the plane occupancy of the machine tool.

3. The inclined guide rail for easy chip removal also facilitates the concentration of iron chips on the chip conveyor for automatic chip removal. The iron filings under cutting carry high heat, and the accumulation on the guide rail will cause the guide rail to be heated and deformed, which will change the working accuracy, and will cause batches of workpieces to be scrapped in the batch automatic machining process. The maintenance of the inclined bed CNC lathe is analyzed as follows:

In order to ensure the working accuracy of the inclined bed CNC lathe and prolong its service life, reasonable maintenance work must be carried out on the self-use inclined bed CNC lathe. The maintenance of the lathe directly affects the processing quality and production efficiency of the workpiece. When the lathe has been running for 500 hours, the first level of maintenance is required. The maintenance work of the inclined bed CNC lathe is mainly carried out by the operator, and the maintenance worker cooperates. During maintenance, you must first cut off the electric probe, and then perform maintenance according to the maintenance content and requirements.

Post time: Sep-30-2021