China Wholesale Alloy Wheel Cnc Lathe Machine Factories Quotes - TCK500D – Lu Young

China Wholesale Alloy Wheel Cnc Lathe Machine Factories Quotes - TCK500D – Lu Young Detail:

Feature

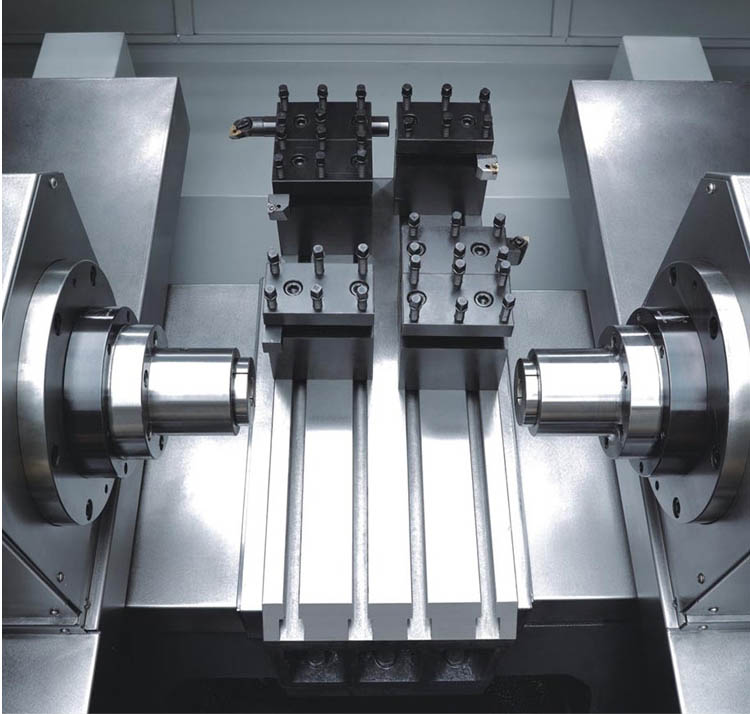

Turning-milling compound machining is one of the most popular machining techniques in the field of machining.It is an advanced manufacturing technology. Compound processing is to put several different processing technology, in a machine tool to achieve.Composite processing is the most widely used, the most difficult, is the turning and milling compound processing. Turning and milling compound machining center is equivalent to a CNC lathe and a machining center compound.At present, the turning and milling compound machining machine tools in China are generally similar to the horizontal structure of the lathe, between the spindle and the tail top, or between the two spindles set adjustable movement of the knife tower, knife tower can clamp the turning tool and used to drive the milling cutter rotation shaft, so that the machine tool has the function of turning and milling.

Specification

| Max swing over bed dia. | mm | 550 | |

| Maximum cutting length | mm | 500 | |

| Maximum cutting diameter | mm | 360 | |

| Type and code of spindle end | A2-6 | ||

| Main/SUB motor power | KW | 7.5/5.5 | |

| Main/sub spindle hole diameter | mm | 66/52 | |

| Main/sub spindle turning speed range | rpm | 280-3500 | |

| Chuck | Diameter/type of chuck | mm | 8² |

| X axis fast moving speed | m/min | 16 | |

| Z1/Z2 axis fast moving velocity | m/min | 16 | |

| Tilt Angle DEG | 45 ° | ||

| Moving distance X/Z | mm | 300/1000 | |

| Fast moving speed X/Z | m/min | 20/24 | |

| Servo motor torque X/Z | NM | 10/15 | |

| Ball screw diameter of 40 mm | 40Φ x12 / X/Z 40 x12 | ||

| The X axis stroke | mm | 300 | |

| Z1 and Z2 axis stroke | mm | 1000/700 | |

| Tool post form | 12 station living turret | ||

| tool dimension | bullnose tool | mm | 25×25 |

| Wight | kg | 5000 | |

| Size | mm | 2500×1900×1930 | |

Advantages

1. The spindle of the machine tool is a high-precision through-hole spindle unit, which is arranged by large-diameter precision bearings with good rigidity and high precision. It is lubricated by grease and assembled under constant temperature and purification environment.

After precision static balance test, the spindle can be guaranteed to run smoothly. Under the drive of AC motor, it has good stiffness and large torque at low speed.

2. Adopt wide span Taiwan linear guideway or German linear guideway, the machine tool bears large load, good dynamic response, eliminates low speed crawling, and has good precision retention.

3. The integral high strength cast iron bed is made of resin sand by professional foundry manufacturers, which has sufficient rigidity, good vibration absorption and thermal stability.

4. The machine tool adopts ball screw made in Taiwan, Z-axis ball screw, X-axis ball screw using tensile structure, improve the accuracy of the workpiece processing of the outer circle and the size of the inner hole.

5. High stability of electrical appliances and long service life.

6. The machine adopts eight-position hydraulic tool rest.Tool change quickly, reliable, high efficiency of hydraulic chuck, stable accuracy.

Our factory

shandong luyoung machinery Co., Ltd. is a company including active and professional teams, specialized in CNC vertical machine Center, CNC Lathe Machine, cnc milling machine. Our team have great experience on manufacturing and exporting. Our service department has experienced technicians that can offer you answers to your technical questions, and in many cases, solve your problem effectively over the phone. We are dedicated to provide customers with the best, highly value added machines. We have earned a strong reputation in design and manufacturing of a wide variety of CNC machine tools. We continuously improve the performance level of our machines, strengthen our quality control system, and offer worldwide support services. Our dedication to the global marketplace will create a new era of CNC machine tools.

Our certification

Pre sale service

1. Customers provide the detailed work piece size or drawing, our professional engineer will check and recommend suitable machine model for you.

2. Or customers send us samples by courier, we can process some samples for customers checking.

3. We can customize machine for customers’ requirements.

4. Welcome customers can come to our factory company for visiting and checking machine.

Product detail pictures:

Related Product Guide:

We have the most advanced production equipment, experienced and qualified engineers and workers, recognized quality control systems and a friendly professional sales team pre/after-sales support for China Wholesale Alloy Wheel Cnc Lathe Machine Factories Quotes - TCK500D – Lu Young , The product will supply to all over the world, such as: Pakistan, Guatemala, Argentina, We always stick to the tenet of "sincerity, high quality, high efficiency, innovation". With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our products, and we are sure that we will offer just what you want, as we always believe that your satisfaction is our success.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.