China Wholesale 4 Axis Machining Center Factories Quotes - TCK36 China factory price metal cnc turning slant bed lathe machine – Lu Young

China Wholesale 4 Axis Machining Center Factories Quotes - TCK36 China factory price metal cnc turning slant bed lathe machine – Lu Young Detail:

Specification

|

Item |

Unit |

Tck36 |

|

Max. spindle speed |

rpm |

3500 |

|

Spindle runout |

|

0.01 |

|

Spindle bore |

mm |

36 |

|

Spindle motor power |

kw |

3 |

|

X axis travel |

mm |

500 |

|

Z axis travel |

mm |

230 |

|

X/Z axis Traverse |

m/min |

20 |

|

Y axis Traverse |

m/min |

|

|

Cutting feed |

mm/rev |

0.001-500 |

|

Slant bed degree |

° |

30 |

|

Repositioning accuracy |

mm |

±0.01 |

|

Cooling system |

|

China water pump |

|

CNC Control System |

|

GSK980TDC full set of GSK |

|

Ball screw |

|

Taiwan |

|

Guide rail |

|

Taiwan Hiwin |

|

Chuck |

|

Collets |

|

Overall dimensions (machine) |

mm |

1960*1390*1750 |

|

Overall dimensions (with wooden case) |

mm |

2260*1690*2050 |

|

Weight (net) |

kg |

2000-2300 |

|

Weight(gross) |

kg |

2100-2400 |

|

Quantity |

set |

2-4 |

|

Lead Time |

working days |

35 |

Product details

1. Fully enclosed protection, better waterproof performance; specially designed to realize various automatic feeding schemes such as oil bath, gas bath, vibrating plate, manipulator, etc.

2. External hydraulic supply unit adopts hydraulic cylinder clamping method. The hydraulic supply unit is designed externally, the oil tank volume is enlarged, the heat dissipation is better, and the work is more stable.

3. High rigidity, high precision, and expandable spindle feed mechanism. Flat/inclined bed is optional. The 30° inclined bed is convenient for chip removal and saves the whole machine space. The stroke of the flat bed remains unchanged, and the internal space is larger. It can realize the combined processing of turning, milling, drilling and tapping. Castings adopt a variety of anti-deformation techniques such as heat treatment and time effect. The X-axis is equipped with a high rigidity design, which can improve the durability and fatigue damage of the tool, and increase the durability.

4. High-speed head assembly, containing 4 paired angular contact high-speed bearings, self-contained encoder synchronous wheel component, labyrinth reinforced waterproof structure, universal for pellets/bars, 25/36 through holes optional, support 6-inch hydraulic Chuck.

5. Stable high-speed spindle, rated speed 6000rpm, Max speed temperature rise 15℃, dynamic balance G1mg, cone oscillation 0.003mm, grease lubrication.

6. Japanese Seiko angular contact ball bearings use long-life bearing steel (Z steel) as the standard material, and the rolling fatigue life is 1.8 times that of ordinary bearing steel.

7. Taiwan Hiwin/Kate linear guide, fast running speed, high machining accuracy, long service life and low replacement cost. Hard rail wear requires re-casting the large part, or even scrapping the machine tool, while the linear guide can be simply replaced.

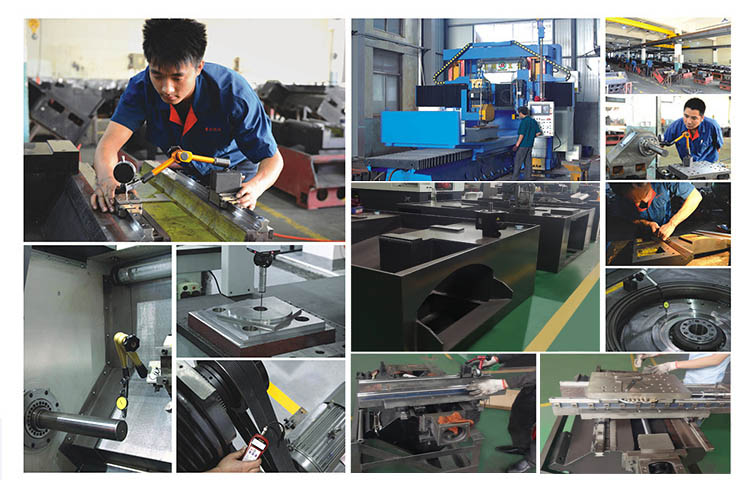

Processing details

We provide you with a complete set of customized processing solutions, tailor-made technical service support for machine tools, we have high-quality trainers to teach you technical support, and experienced engineers to guide you. The company attaches great importance to the construction of the talent team, and has recruited a group of experts with scientific research spirit and mastering the core technology of contemporary machine tools. Each process is assembled according to standards.

Executive standard

1. GB/T 25659.1-2010 Simple CNC Horizontal Lathe Part 1: Accuracy Inspection.

2. GB/T 25659.2-2010 Simple CNC Horizontal Lathe Part 2: Technical Conditions.

3. GB/T 25376-2010 General technical requirements for metal cutting machine tools and machining parts.

4. GB/T 25373-2010 General technical requirements for assembly of metal cutting machine tools.

Why choose our slant bed cnc lathe machine?

1. Strong strength, The company has 20 years of production experience, rich product range to meet the needs of different customers.

2. Quality product, Workshop workers skilled and rigorous testing of product quality, strict control of each production process.

3. Direct factory price, provide competitive factory price and save your costs.

4. 7×24 hours after-sale service, Any questions, please contact us directly at any time.

5. Strong packing, will protect the goods from any possible damage during transit.

Product detail pictures:

Related Product Guide:

Sticking for the perception of "Creating products of top quality and producing friends with people today from all around the world", we constantly place the desire of shoppers to start with for China Wholesale 4 Axis Machining Center Factories Quotes - TCK36 China factory price metal cnc turning slant bed lathe machine – Lu Young , The product will supply to all over the world, such as: Costa rica, Cape Town, Romania, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you personally.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.