XK7124 Small high precision cnc milling machine

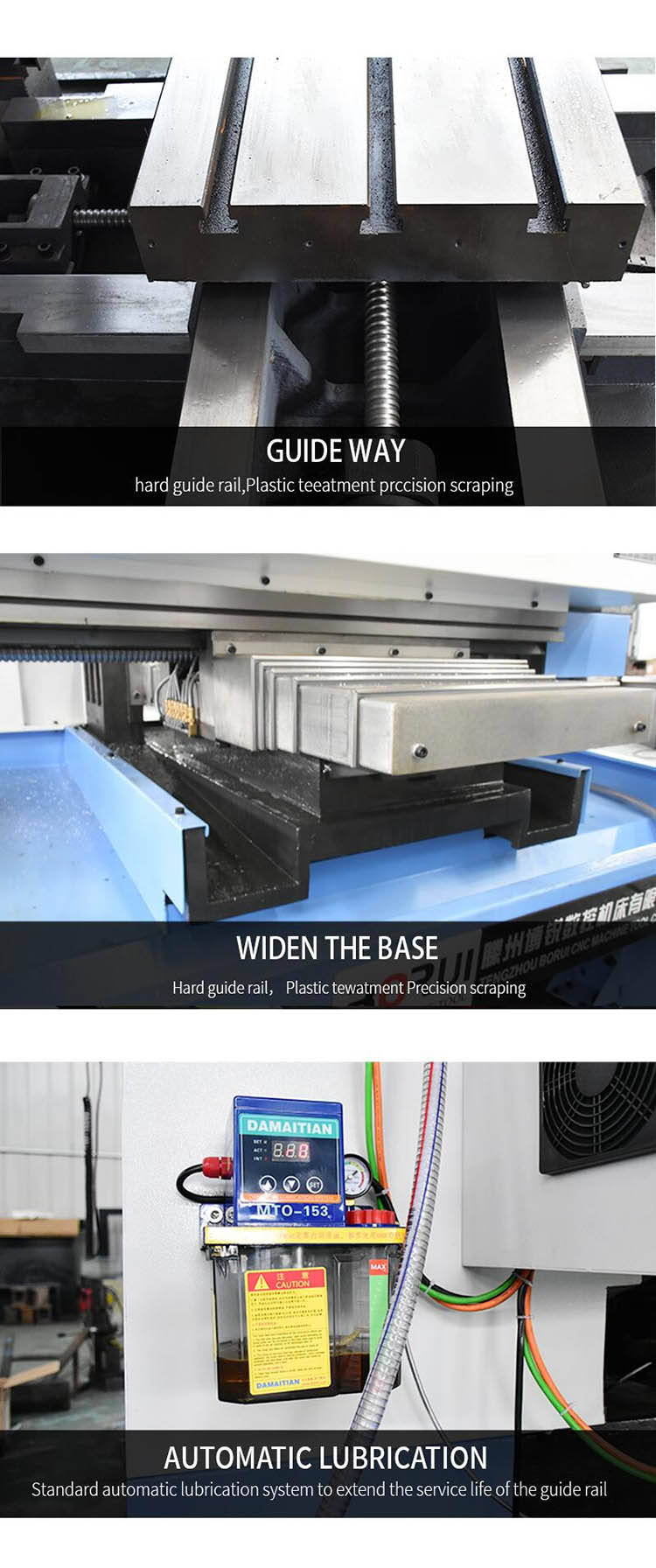

China XK7124 Small high precision cnc milling machine sells small and medium-sized factory price CNC milling machine The hard rail machine series is a three-axis sliding vertical processing center, which can be used for medium parts and die processing.The castings are cast in resin sand technology, and the large parts are all HT250 materials, and the internal stress of the casting is eliminated through the manual aging process of the multi-channel process to ensure the stability of the casting.X/Y/Z triaxial guide rail is used in the guide rail, with high rigidity, low noise and low frictional characteristics. It can be moved quickly and obtain the best round accuracy. The contact surface is made of imported high-wear-resistant plastic soft belt. After hardened treatment of guide rail, precision grinding and scraping process are used to obtain the best straightness and dynamic accuracy. The gauge guide width, thickness and guide rail span are bigger than the same type, with better stability and more carrying capacity.

Specification

|

CNC Milling Machine |

XK7124 |

|

Size of worktable(length×width) |

800mm×240mm |

|

T slot (width x qty x spaces) |

16mm×3×60mm |

|

Max loading weight on worktable |

60Kg |

|

X-Axis travel |

430mm |

|

Y-Axis travel |

290mm |

|

Z-Axis travel |

400mm |

|

Distance between spindle nose and table |

50-450mm |

|

Distance between spindle center and column |

297mm |

|

Spindle taper |

BT40 |

|

Max. spindle speed |

6000r/min |

|

Spindle motor power |

3.7Kw |

|

Feeding Motor power: X Axis |

1Kw |

|

Y Axis |

1Kw |

|

Z Axis |

1Kw |

|

Rapid feeding speed: X,Y,Z axis |

10m/min |

|

Feeding speed |

0-12000mm/min |

|

Min. set unit |

0.001mm |

|

Max. size of tool |

φ60×175mm |

|

Loosing and clamping way for tool |

Clamp by disc spring |

|

Loose manually |

|

|

Clamp by disc spring. |

|

|

Loose pneumatically |

|

|

Max. loading weight of Tool |

3.5Kg |

|

N.W (include machine stand) |

1500Kg |

|

Packing size( L X W X H) |

1220×1380×1650mm |

Machine features

Vertical machining center is shandong Luyoung CNC Machineryry Co., Ltd. introduced advanced technology to produce a new generation of CNC machine tools, the machine tool unique firm and durable rigid main structure, through the repeated simulation and calculation of engineering mechanics, the design of firm and stable bed structure, to achieve the rigid doubling and quality reduction of engineering needs.Full hardening of the sliding rail, with precision grinding processing, combined with a satisfactory quality of precision.It is not only suitable for plate, plate, shell, precision parts processing, but also suitable for mold processing. The machine is equipped with automatic tool exchange system, fully enclosed protective cover, automatic lubrication system, cooling system, chip removal device, and portable manual operation device. Parts can be completed after a clamping milling, boring, drilling, expanding, reaming, tapping and other processes, with a high degree of automation, strong reliability, simple operation, convenient, pleasant, the overall appearance of beautiful, high degree of mechanical and electrical integration advantages.

Why choose us?

1. Company strength.We have 20 years experiences for cnc machine profuction.

2 .Friendly price.We supply friendly factory price to help you establish your advantage in your local market

3. Training for free. We can supply training for you in our factory for free. Oversea service also is OK.

4. Relationship. We will establish long-term relationship with our clients.

FAQ

1. What's the term of payment ?

As usual, Our term of payment is:

30% downpayment by T/T (Telegraphic transfer ) in advance.

70% by T/T before shipment.

Besides, We can also accept term of payment by irrevocable letter of credit at sight. D/P or D/A.

2. What's the quality warranty?

We will supply standard parts and accessories with our machines when shipment. Within one year after receiving our machines, In the right operation, If there are any damaged parts or accessories, We will replace them by air-mail or express mail immediately free of charge.

3. What's the delivery time?

We will supply goods to you within 1 months after getting your 30% downpayment by T/T according to the different products.

4. What's the charge of installing and commissioning?

For some machines, It need our technician to go to your local site and help you install and commission machines. At the same time, Our technician will train your workers. It will take 7-15 days for different machines. The return air-tickets, accommodation, food, salary ( USD60.00/day for every technician ), etc will be born by the end-user.