1.Casting: HT300 resin sand wear-resistant castings have high density and good wear resistance! The saddle adopts a double-layer casting structure, and the large A-shaped column structure shows high rigidity cutting ability.

2. Spindle: adopts Taiwan high-speed spindle 8000rpm, simple and compact structure, high efficiency, low noise, low vibration and high precision.

3.Screw: The guide screw adopts the imported JIS-C3 grinding grade pre-stretched nut screw to eliminate the backlash, after heat treatment, it has good rigidity, wear resistance, and guarantees the high precision of the operation.

4. Auto tool changer: Taiwan hat type (16 knives) tool magazine. Advantages: low wear, long life, easy adjustment, and low failure rate.

5.Testing: All the factory equipment has gone through the inspection steps of laser interference, copy machine, actual measurement, etc.Ensure the production quality of each product.

|

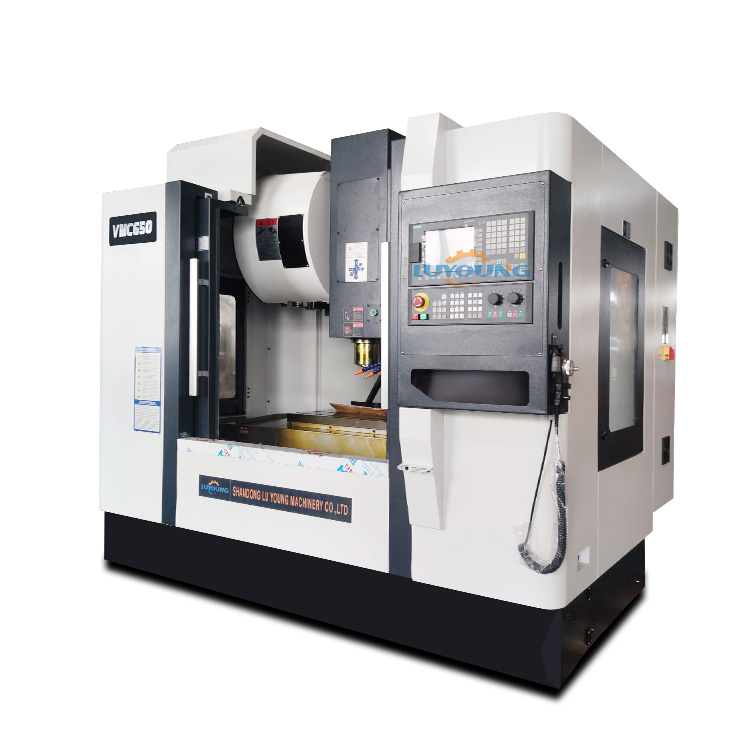

CNC Milling Machine |

VMC650 |

| X travel (mm) | 650 |

| Y travel (mm) | 450 |

| Z travel (mm) | 500 |

| Table size(L×W) (mm) | 900×400 |

| Max load (kg) | 400 |

| Spindle center to column (mm) | 575 |

| Spindle nose to table (mm) | 100~600 |

| Ball screw | 4012 |

| X,Y,Z cutting speed (mm/min) | 1-6000 |

| X,Y,Z fast speed (m/min) | 15 |

| Spindle speed(r/min) | 50~8000 |

| Spindle taper | BT40 |

| Spindle motor (kw) | 5.5 |

| T slot(mm)quantity×width×distance | 5/18/75 |

| Accuracy (300mm) | 0.005 |

| Repeatability accuracy(300mm) | 0.003 |

| Air pressure (Mpa) | 0.6 |

| Size (L×W×H)(m) | 2.65*2.15*2.55 |

| weight(T) | 4.0 |

Post time: Dec-20-2021