Specification:

|

CK6180 Series |

|

| Max. swing over bed (mm) | φ800 |

|

Max. swing dia. over cross slide(mm) |

φ500 |

|

Width of guide way(mm) |

600 |

|

Max.processing length(mm) |

1500/2000/3000 |

| Form | no gears |

| Range of spindle speed(r/min) | 25-850 rpm |

| The spindle terminal structure | C11 |

| Diameter of spindle bore (mm) | φ105 |

| The taper of spindle front-end | (Metric)120 1:20 |

| Power of main motor (KW) | 15KW |

| Position accuracy(mm) | ±0.007 |

| repeated positioning accuracy(mm) | ±0.006 |

| Processing accuracy(mm) | IT6-IT7 |

| Surface roughness | Ra1.6 |

| Sleeve diameter of tailstock (mm) | φ100 |

| Sleeve travel of tailstock (mm) | 250 |

| Cone hole taper of tailstock’s sleeve | MT6 |

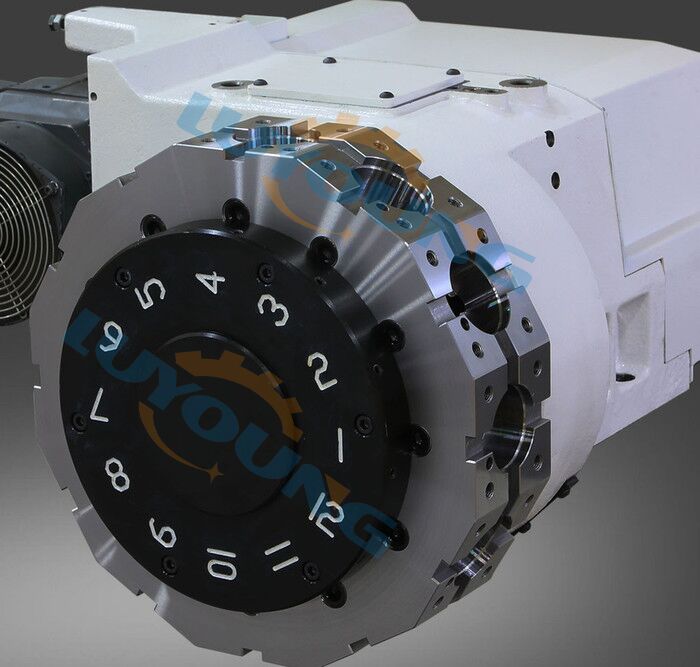

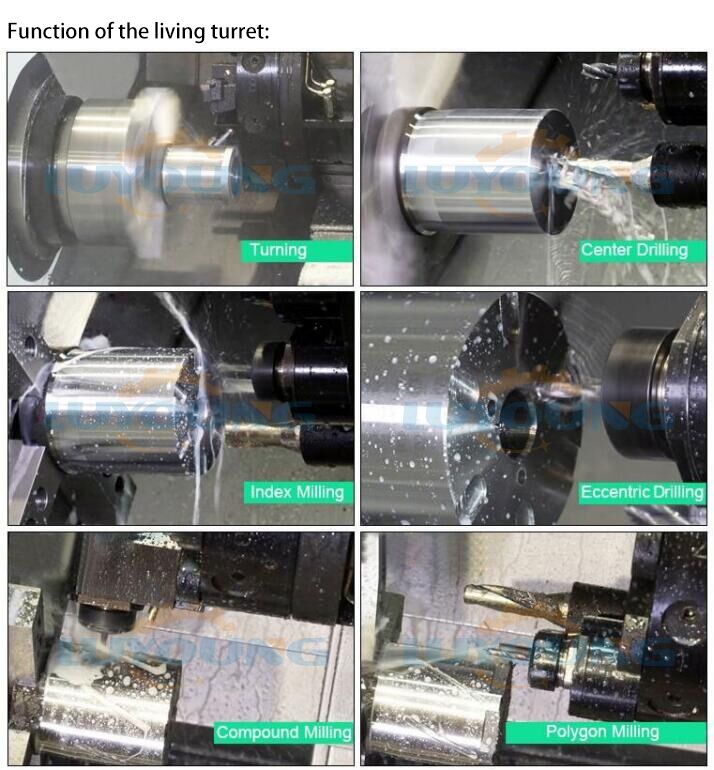

| Turret | 12 station living turret(BMT45) |

| Y axis travel range | 160mm |

| living tools driving motor | 2.2kw |

| living tools speed | 3000rpm |

| Restting accuracy (mm) | 0.01 |

| Length of section of knife handle (mm) | 32×32 |

| Length*width*height | (3298/3800/4800)x1660x1690 |

| Gross weight (Kg) | 4000/4500/5500kg |

Feature of CK6180 Heavy duty flat bed CNC lathe and milling machine combo with 12 station living turret :

1.Bed casting.Integrated structure of bed casting, width of guide rail 550mm, high frequency quenching 5mm, hardness 53-56 degrees, high base strength, strong suitability force cutting.

2. Guide rail:And after two artificial aging treatments, the surface of the bed guide rail is quenched, with a hardness of HRC50, good stability and high strength.

3.Spindle:45#steel forged spindle,feature is high speed, high precision, strong rigidity, small thermal deformation, stable operation and low noise. The single-side feed is nearly 5MM, and the processing efficiency is significantly higher than similar products.

4.Chuck:Precision self-centering chuck, standard three-jaw manual chuck. Optional 4-jaw hydraulic chuck or pneumatic chuck

5.Tool post:The electric four-station tool post adopts precision gear plate positioning, which has high repeat positioning accuracy

6.Tailstock: The tailstock has a fast cam clamping device, which has high working efficiency. There is a device in the tailstock sleeve to prevent the rotation of the drill bit,

which avoids damage to the taper of the inner hole of the tailstock sleeve due to misoperation of the drill bit,and effectively protects the tailstock components.

Post time: Sep-16-2021