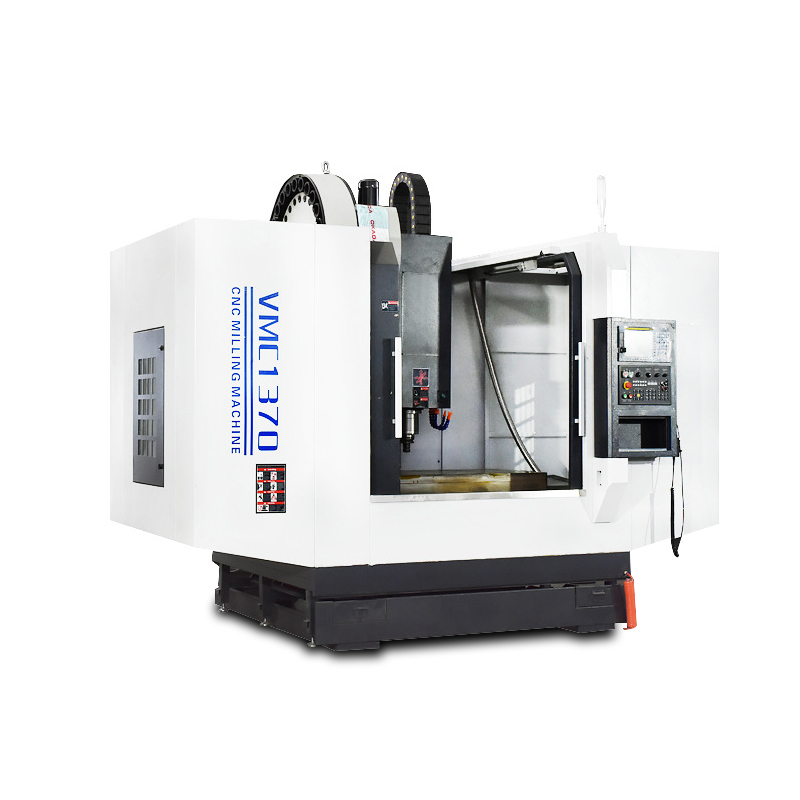

VMC1370 vertical machining center is a large CNC machining center, it has a larger stroke and work table than small machining center, It can meet high-speed drilling and tapping at the same time, and it is especially suitable for the processing industry of IT and auto parts. It can be used for vertical milling, drilling, expanding, boring, tapping and other processing procedures, and has a wide range of uses. The feed axis of the machining center is controlled by three coordinates of X, Y, and Z, and the main shaft is driven by a servo motor. It can clamp various complex parts such as disks, plates, shells, cams, and molds at one time to complete drilling. , Milling, boring, expanding, reaming, tapping and other processes, suitable for processing various medium-sized workpieces, and also suitable for processing various complex shapes and surfaces, especially for processing parts with three-dimensional shapes. Therefore, it is an ideal machine tool for mold manufacturing.

VMC1370 machining center of XYZ axis travel is 1300×700×700mm, BT50 Taiwan spindle, speed of 8000 RPM, spindle motor power is 15KW.

Product Feature

●The fuselage and main components are all H300 high-strength cast iron with stable structure and organization to ensure the stability of the machine tool for long-term use;

●The bottom of the column is an A-shaped bridge-span structure, combined with a large box base, which greatly reduces the vibration of the machine body during heavy cutting;

●Pre-stretched Taiwan Precision Yintai Class C3 ball screw drive;

●Three-axis adopts high-precision roller screws, and Y-axis adopts four-rail structure, which has strong stability and processing efficiency.

●Taiwan high-speed, high-precision, high-rigidity spindle unit;

●Oil-water separation design

●Intermittent automatic lubrication;

●Pneumatic loosening and broaching system

With P4 bearings, the entire spindle is assembled under constant temperature conditions to ensure spindle rotation accuracy.

Why choose our vmc1370 cnc milling machine?

1. The casting adopts resin sand molding process, two annealing qualitative treatments, two artificial aging vibrations, and natural aging to ensure the quality of the castings.

2. Large parts are processed with German Wagereisi grinders.

3. Wiring gauge can be selected. The X, Y, and Z axes adopt the original Taiwan Silver Roller Heavy-Duty Guide, and the linear rail slide is specially customized to be widened and enlarged, especially the Z-axis slide. The roller heavy-duty linear guide can not only meet the customer’s requirements for high speed and high precision, but also can cut forcefully, and at the same time increase the service life of the machine tool guide.

4. NSK rolling bearings are generally composed of ferrules, rolling elements and cages. According to the load bearing direction, it can be divided into radial bearings and thrust bearings. The structure around the imported bearing is simplified, which is convenient for maintenance and inspection. It is easier to use under high and low temperature conditions. In order to improve rigidity, it can be used even in negative clearance (preload state)

5. Hat-type tool magazine: standard economical type, original ball-type cam mechanism, high segmentation accuracy. The separate tool holder is supported by the cutter head to maintain the verticality and clearance of the cutter bar for a long time, and the knife taking action is smooth.

Post time: Aug-05-2021