GB4220 high quality metal band saw machine

Specification

|

Metal band sawing machine parameters |

GB220 |

|

Cutting range(mm) |

200-200*200 |

|

Saw band specification(mm) |

2650*27*0.9 |

|

Band saw speed(m/min) |

27, 45, 69 |

|

Mode of intensification of work |

Manual / hydraulic |

|

Main motor power(kw) |

1.5 |

|

Hydraulic motor power(kw) |

0.75 |

|

Cooling pump power:(kw) |

0.04 |

|

outline dimension(mm) |

1400*800*1100 |

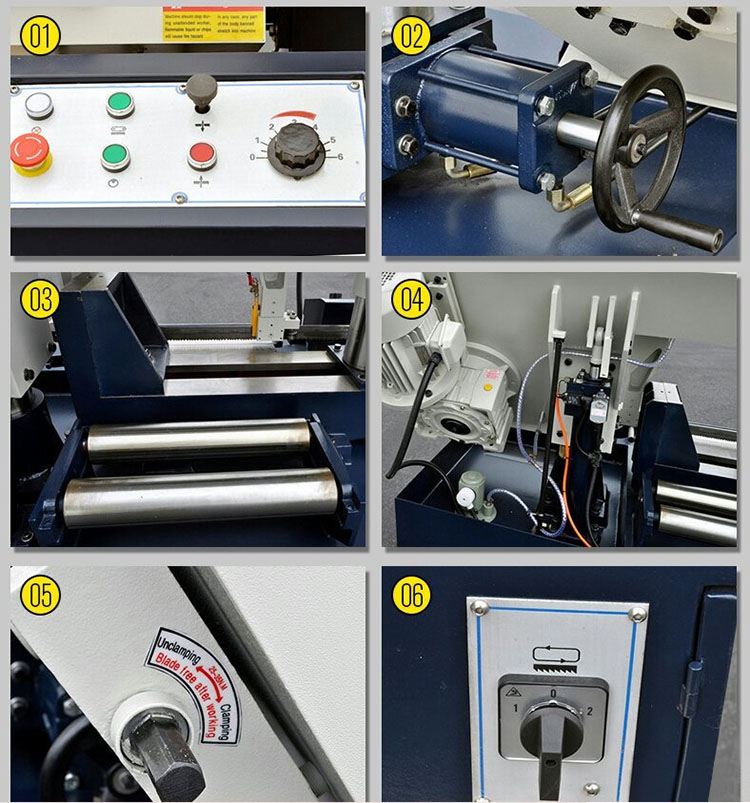

Features

1. Cutting speed hydraulic control, stepless speed regulation;

2. The structure of the guide block is scientific and reasonable, which can extend the service life of the saw blade;

3. Double column structure, stable operation;

4. Stable sawing and high precision;

5. The working clamping adopts hydraulic clamping, which is easy to operate.

6. Three-way hydraulic clamping device can be customized.

Safety operation rules for metal band sawing machine

1. The operation and maintenance personnel of the band sawing machine must be professionally trained to master the operation and maintenance skills of the band sawing machine. Operators should ensure adequate sleep and maintain concentration.

2. When changing the speed, you must stop before opening the protective cover, turn the handle to relax the belt, place the V-belt in the groove of the required speed, then tension the belt and cover the protective cover.

3. The adjustment of the chip removal wire brush should make the wire contact the tooth of the band saw blade, but not beyond the root of the tooth. Pay attention to whether the wire brush can remove the iron filings.

4. Adjust the guide arm along the dovetail rail according to the size of the workpiece to be processed. After the adjustment, the guide device must be locked.

5. The large diameter of the saw material Z must not exceed the regulations, and the workpiece must be clamped firmly.

6. Band saw blade tightness should be proper, speed and feed must be proper.

7. Cast iron, copper, aluminum parts do not need cutting fluid, and others need to write fluid.

8. The saw blade breaks during cutting. After replacing the saw blade, the workpiece must be turned over and sawed again. The saw bow should be lowered slowly without impact.

9. During the cutting process, the operator is strictly forbidden to leave the post, and to operate with gloves is strictly prohibited.

10. At the end of each shift, you must cut off the power supply, open the protective cover, remove the chips brought into the saw wheel, and do a good job of daily maintenance and surrounding cleaning.

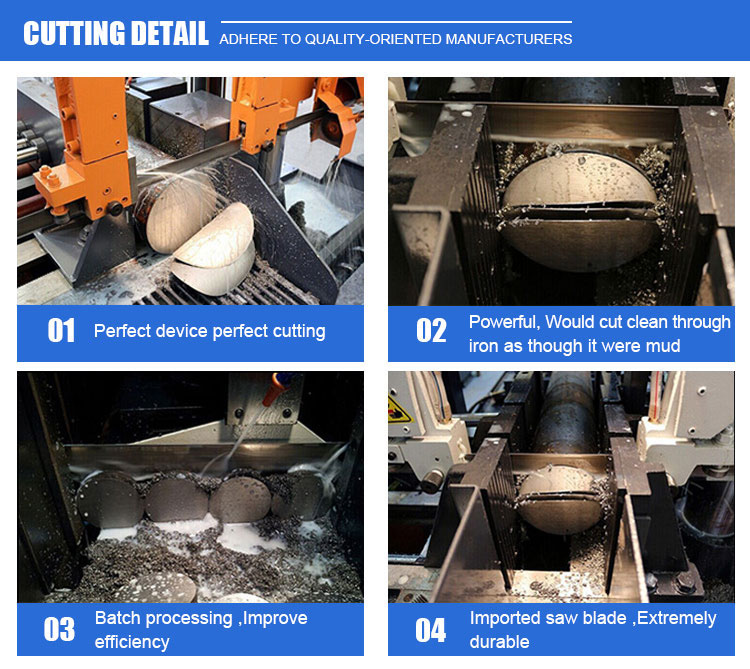

Cutting detail

Mainly used for sawing various metal materials such as carbon structural steel, low alloy steel, high alloy steel, special alloy steel and stainless steel, acid-resistant steel, etc.

1. Perfect device perfect cutting

2. Powerful,would cut clean through iron as though it were mud

3. Batch processing, improve efficiency

4. Imported saw blade, extremely durable